Compared with the previous generation of hollow glass magnesium composite panels, the magnesium oxysulfide purification panels developed and produced by LAIRUN have the following advantages:

100% guaranteed absolutely no halogen reversion:

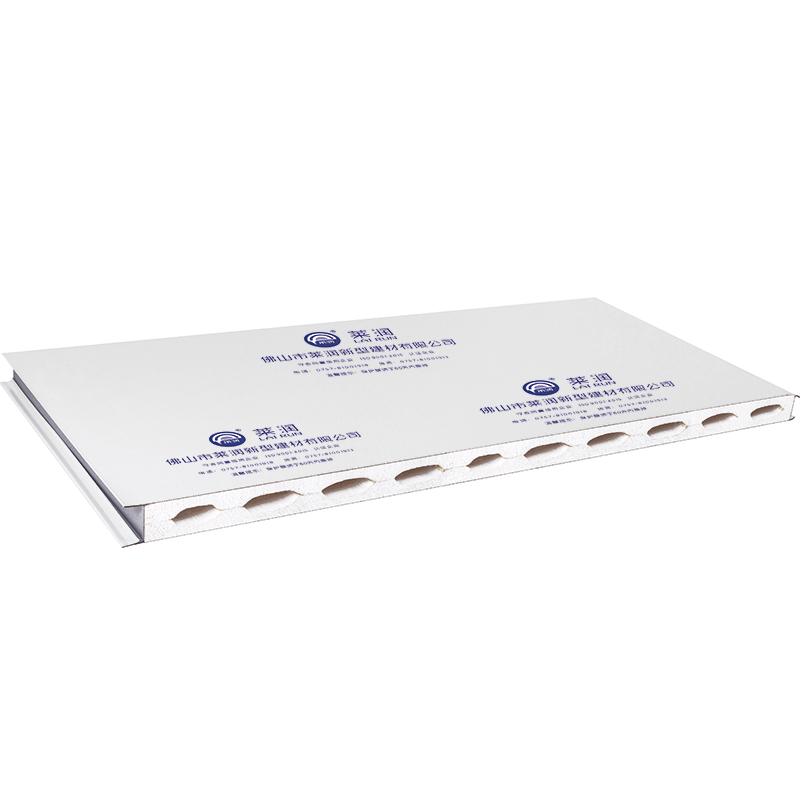

Utilizing an arch bridge structural principle, localized stress is dispersed effectively. The magnesium oxysulfide core is integrally molded in upper and lower layers within a mold, requiring minimal glue for bonding. This significantly reduces deformation caused by pressure or thermal expansion and contraction. Its load-bearing capacity is twice that of hollow glass magnesium panels, offering excellent stability. The panel is water-resistant, moisture-proof, unaffected by condensation or humid air, and does not exhibit halogen reversion or release white crystalline substances.

Fire resistance:

The panel has superior fire resistance, achieving a non-combustibility rating of GB8624-1997 Class A. It has a low thermal conductivity and can withstand local exposure to temperatures of over 1,000°C without heating the back surface. The burnt area does not expand or spread, and no smoke, toxins, or pollutants are released during combustion.

Flatness:

The magnesium oxysulfide composite panel boasts a surface flatness superior to other core materials. Due to the low thermal expansion and contraction coefficient of the core material and precise one-time cutting by imported electronic precision saws, the overall flatness error is controlled within 0.1 mm. This is significantly better than other materials, which often require secondary manual adhesion and can result in errors exceeding 1 mm, causing visible seams on the surface after processing.

Durability:

The molecular structure of magnesium oxysulfide is stable and resistant to aging. It remains unaffected by laboratory humid and rainy weather conditions or immersion in water. The material does not corrode aluminum, rivets, or steel, offering resistance to corrosion, bacteria, insects, and termites. The service life is no less than 20 years.